Portable Clamp-On Ultrasonic Flow Meter

ATO manufactured portable ultrasonic flow meter is designed for wide pipe sizes ranging from 40mm to 1200mm in nominal diameter with accuracy ±1% of reading. Big LCD display, built-in large capacity data logger, batteries-powered for long working. With clamp-on installation, the non-invasive flow meter from Chinese supplier is easy to install, convenient to operate, and less maintenance, suitable for virtually all pure liquids like water, gasoline, oils and so on. Wholesale price, high accuracy and good repeatability.

Features:

- Convenient use, fast testing & less maintenance. The Chinese noninvasive ultrasonic flow meter can measure the liquid flow rate inside the pipe without disassembling the pipe and pressure loss

- Applicable for various pure liquids including water, tapwater, seawater, beers, lubricants, gasoline, cooking oil, etc.

- Compatible with various material pipes like cast iron pipe, galvanized pipe, stainless steel pipe, PVC pipe, aluminum pipe, etc. The flow meter with the proper clamp-on transducer does well in these applications.

- Measuring diameter covers a wide range of DN40-DN1200, suitable for all kinds of industrial site installation and use.

- Big LCD display the instantaneous flow rate and cumulative flow rate at the real time.

- Built-in data logger, the ultrasonic flowmeter can storage 2000 lines of data.

Specification:

| Model | ATO-SPE-2000H |

| Accuracy | ±1% of reading @ flow rate >0.2m/s |

| Linearity | 0.50% |

| Repeatability | 0.20% |

| Response Time | 0-999 seconds, user-selectable |

| Velocity | 0.2~32m/s |

| Pipe Size | 40mm-1200mm |

| Totalizer | 7-digit totals for net, positive and negative flow respectively |

| Liquid Type | Virtually all liquids |

| Transducer (Optional)* | Standard clamp-on transducers: small/medium/large; High-temperature clamp-on transducers: small/medium/large (See the "Transducer Selection" table below for the details) |

| Protection Grade | Transducer: IP67 |

| Transducer Cable Length | Standard 5m x 2 |

| Operating Temperature | Main unit: -30℃~90℃, Transducers: -30℃~160℃ |

| Operating Humidity | Main unit: ≤85%RH |

| Power Supply | 3 AAA built-in Ni-H batteries (Can work over 12 hours after a full charge), external charger with 100V-240VAC |

| Display | 4 x 16 English letters |

| Signal Output | OCT output (6~1000ms) |

| Data Logger | Built-in data logger, can store over 2000 lines of data |

| Housing Material | ABS |

| Main Unit Size | 100x66x20mm |

| Main Unit Weight | 500g with batteries |

Note: For more information, please click portable ultrasonic clamp-on flow meter user manual. If you don't find the flow meter you want to buy, please contact us

Transducer Selection:

| Transducer | Measuring Pipe Size Range | Temperature Range | Dimensions (mm) |

| Standard clamp-on transducer - Small (TS-2) | DN40-DN100 | -30℃~90℃ | 45*25*32 |

| Standard clamp-on transducer - Medium (TM-1) | DN50-DN700 | 64*39*44 | |

| Standard clamp-on transducer - Large (TL-1) | DN300-DN1200 | 97*54*33 | |

| High-temp clamp-on transducer - Small (TS-2-HT) | DN40-DN100 | -30℃~160℃ | 45*25*32 |

| High-temp clamp-on transducer - Medium (TM-1-HT) | DN50-DN700 | 64*39*44 | |

| High-temp clamp-on transducer - Large | DN300-DN1200 | 97*54*33 |

Transducer Installation:

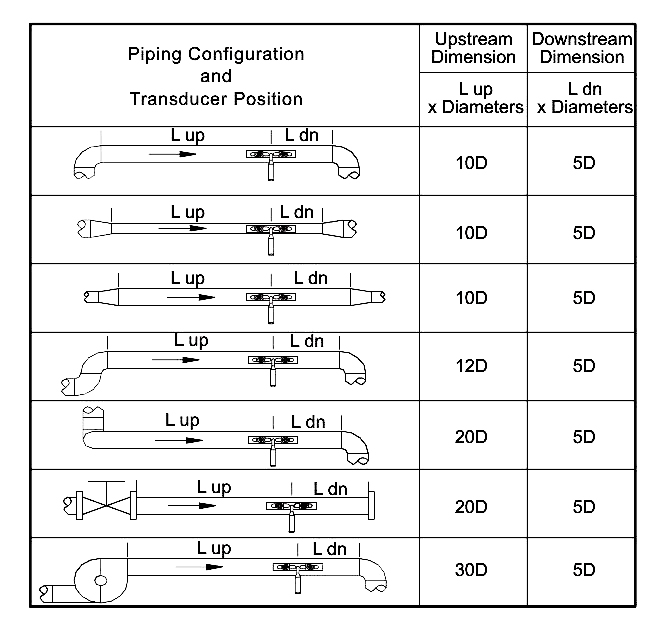

1. Choosing right installation position

- The pipeline where the transducer is installed must have a long enough straight pipe section, of course, the longer the better, generally 10 times the pipe diameter upstream, 5 times the pipe diameter downstream, and 30 times the pipe diameter from the pump port. At the same time, ensure that the liquid in this section must be full.

- Make sure that the temperature range of the pipe under test is within the applicable range of the sensor, usually at room temperature.

- Take the corrosion or scaling of the pipeline into consideration. It is better to choose a newer pipeline for the measurement. If it is not available, subtract the corrosion from the pipe wall thickness or consider scaling as the pipe lining.

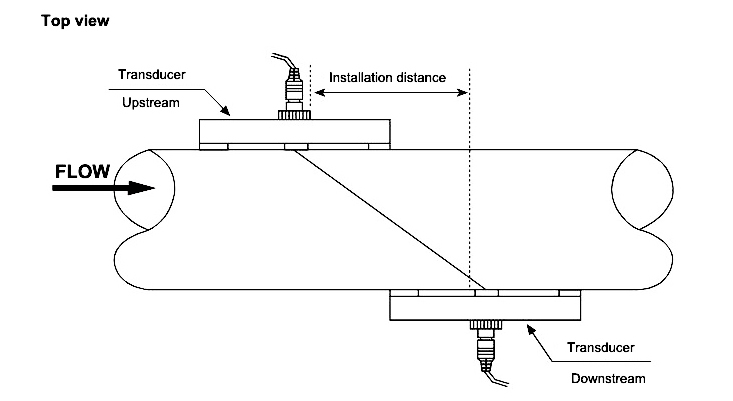

- Z-installation method: generally suitable for the pipes above DN100mm

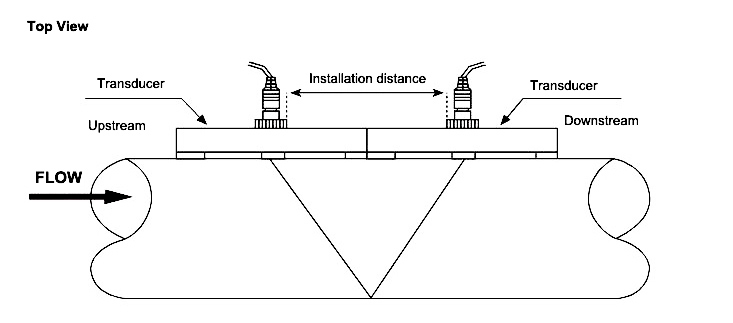

- V-installation method: generally suitable for the DN20-300mm pipes

* The installation distance is shown after entering the pipe parameters into the ultrasonic flow meter.

* The installation distance is shown after entering the pipe parameters into the ultrasonic flow meter.