How does a Flow Meter Work?

The flow meter is the eye of industrial production and occupies an important position and role in the national economy. ATO Chinese flow meter can be used to measure the flow of gas, liquid, steam and other media.

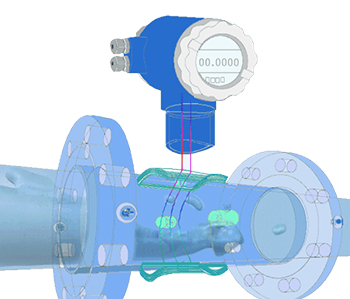

In order to give customers a better understanding of flow meters, atoflowmeter.com will introduce the working principles of different flow meters to you.Magnetic Flow Meter Working Principle

Magnetic flow meter works based on Faraday's law of electromagnetic induction. In the magnetic flow meter, the conductive medium in the measuring tube is equivalent to the conductive metal rod in the Faraday test, and the two electromagnetic coils at the upper and lower ends generate a constant magnetic constant. When a conductive medium flows, an induced voltage will be generated. Two electrodes inside the pipe measure the induced voltage generated. The measuring tube is electromagnetically isolated from the fluid and the measuring electrode by means of a non-conductive lining (rubber, Teflon, etc.).

Magnetic flow meter work characteristics

- It has a bidirectional measurement system.

- The straight pipe section required by the sensor is shorter, and the length is 5 times the pipe diameter.

- Small pressure loss.

- Measurement is not affected by changes in fluid density, viscosity, temperature, pressure and conductivity.

- Mainly used in sewage treatment.

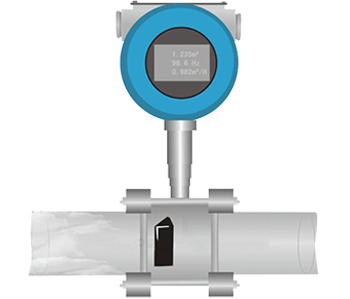

Vortex Flow Meter Working Principle

Vortex flow meters measure flow according to the principle of fluid oscillation. When the fluid passes through the vortex flow meter in the pipeline, two rows of vortices proportional to the flow rate are generated alternately up and down behind the vortex generator of the triangular column. The release frequency of the vortex is related to the average velocity of the fluid flowing through the vortex generator and the characteristic width of the vortex generator. From this relationship, the vortex frequency can be used to calculate the average velocity of the fluid flowing through the vortex generator, which is then multiplied by the cross-sectional area to obtain the flow rate.

Vortex flow meter work characteristics

- Simple and firm structure, no moving parts, high reliability, and very reliable long-term operation.

- Simple installation and very convenient maintenance.

- The detection sensor does not directly contact the measured medium, with stable performance and long life.

- The output is proportional to the flow rate. Proportional pulse signal, no zero drift, high precision.

- Wide measurement range, range ratio can reach 1:10.

- Pressure loss is small, operating cost is low, and it is more energy-saving.

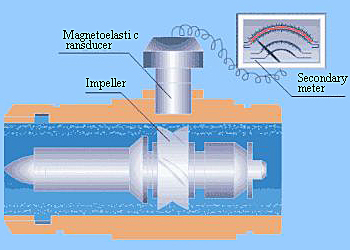

Liquid Turbine Flow Meter Working Principle

The fluid flows through the sensor housing. Since the blades of the impeller of the turbine flow meter have a certain angle with the flow direction, the impulsive force of the fluid makes the blades have rotational torque. After overcoming the friction torque and fluid resistance, the blades rotate, and the rotational speed is stable after the torque is balanced. Under the condition that the speed is proportional to the flow velocity. Because the blade has magnetic permeability, it is in the magnetic field of the signal detector (composed of permanent magnet steel and coil), the rotating blade cuts the magnetic field line, and periodically changes the magnetic flux of the coil, thus The two ends of the coil induce an electrical pulse signal, which is amplified and shaped by the amplifier to form a continuous rectangular pulse wave with a certain amplitude, which can be transmitted to the display instrument to display the instantaneous flow and cumulative volume of the fluid.

Liquid turbine flow meter work characteristics- Strong resistance to impurities.

- Strong anti-electromagnetic interference and anti-vibration capabilities.

- Its structure and principle are simple and easy to maintain.

- There is almost no pressure loss, saving power consumption.